- Home

- Food quality and safety

- Food Safety

Food Safety

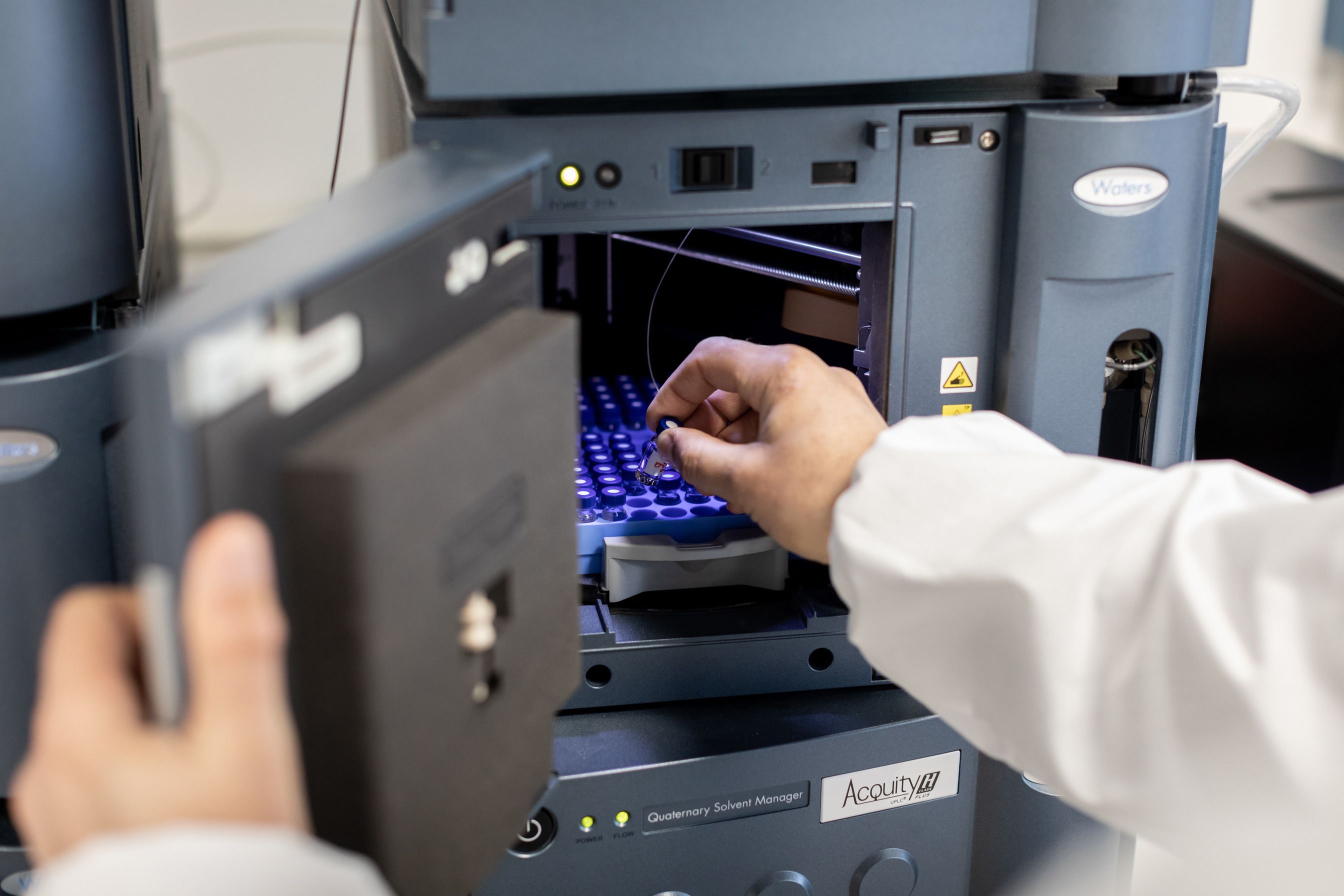

INTEGRATED FOOD SAFETY

Per quanto riguarda la salute e la sicurezza alimentare, tutti prodotti destinati all’alimentazione umana e animale sono valutati secondo le normative HACCP e i vari schemi di certificazione applicati dalle aziende del Gruppo.

Thanks to this approach, the relevant dangers are identified, considering the origin of raw materials and any alerts. The risks are then assessed and control methods are established which can be pre-requirements (PRP) already adopted in the management system, operating PRP and/or CCP (Critical Control Point) which can envisage the execution of specific analysis for each lot.

Multi-disciplinary team technicians re-examine and update the risk assessments linked to each single process/production plant every year. This approach enables us to prevent health and safety non-conformities.

In compliance with the reference standards, Cereal Docks undertakes to implement all measures needed to prevent food fraud and to protect products against intentional contamination and tampering (food defence). It also undertakes to spread the food safety culture through specific training plans for its collaborators.

Traceability from the field to the finished product

LCA STUDIES

Food quality and safety

Research & Innovation

REGISTRO IMPRESE DI VICENZA - CF/P.IVA 02218040240 – CODICE ISO IT02218040240 – R.E.A. VI 215209 – CAP.SOC. 10.000.000 EURO INT.VERS.- SOCIETÀ A UNICO SOCIO